DANIELI AUTOMATION NEWS

2020, 25th September

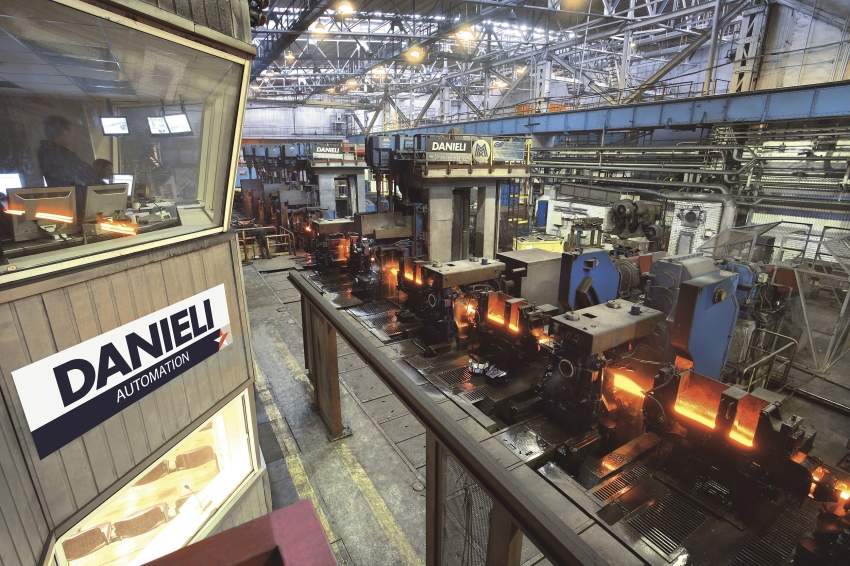

Three Rolling Mills modernized in MMK

Danieli Automation technology solutions to increase plant reliability

After the order given to Danieli Automation in 2019 for robotic solutions for automatic dross removing from the zinc pot with two Q-Robot Zinc to be installed in ANGTS-1 and in ANGTS-2, PJSC Magnitogorsk Iron and Steel Works, based in the Chelyabinsk Region of the Russian Federation, confirmed the confidence on Danieli Automation solutions with a new order for Process Control Systems based on virtualized servers, new Human Machine Interface application and new Ethernet network infrastructure for three rolling mills for long products.

The revamping will include hardware and software for the above systems in the three highly productive 170, 370 and 450 Bars and Big Rounds, Wire Rod and Section Rolling Mills supplied by Danieli in 2004, to substitute the existing systems with new and up-to-date ones. Tasks of the revamping are the Improvement of safety and access to base SW support. The overall reliability of the automation system for these three mills will improve after this modernization.

The supply will include also the support for the onsite activities related to the erection and commissioning which will be realized partially off-line during plants production in order anticipate as much as possible the job which will be finalized during a programmed plants stoppage for general maintenance.